World's first fish farmed on mycoprotein

That is the claim from the company Cirkulär from Lund in Sweden. They have farmed and sold fish without fishmeal for commercial sale. They are now in dialogue with Norwegian feed producers.

According to them, this is the first time fish farmed on mycoprotein has reached the market. The protein is made from yeast cells that have fed on waste from the forestry industry.

Central to this is the company Cirkulär from Lund, which converts industrial side streams from the forestry industry into high-value, circular base ingredients.

After operating a pilot plant in southern Sweden for the past two years, the company is now taking the next step towards a full-scale production facility.

Production of fish based on mycoprotein addresses two global challenges: the fish feed industry's dependence on soy and fishmeal, and the forestry industry's need for circular solutions for its side streams.

The initiative is part of 'Feed of the Future', led by Axfoundation and the Swedish University of Agricultural Sciences (SLU), together with several actors throughout the value chain.

From validation to commercial reality

Since 2023, Cirkulär has operated a pilot factory on an industrial scale in Skåne. Thus, the mycoprotein is made and the bioproduction process has been thoroughly validated. Using a proprietary fungus and fermentation technology, the fungal culture is fed with side streams from the forestry industry and converts these into a circular protein mass that is ideal as fish feed, he further states.

"The facility has demonstrated stable performance and now proves that circular proteins can be produced reliably on a larger scale, the company reports. This breakthrough shows that our technology is not only robust but also commercially viable" says Eric Öste, managing director and founder of Cirkulär to LandbasedAQ.

The fish they have produced is rainbow trout farmed in Älvdalen by the company Älvdalslax.

"We call it the fish of the future, and it is part of the Vinnova-funded project «Framtidens Foder för Fågel, Fisk och Fläsk», where the goal is to replace soy and fishmeal with mycoprotein (as well as insect meal and mussel meal), which are significantly more sustainable at all levels" says the managing director.

He tells the fish had an average weight of 4.1 kg when they started slaughtering.

"So far, 2.4 tonnes out of a total of approximately 6 tonnes are delivered in this first round", he says.

In dialogue with Norwegian players

"Who do you see as potential customers for the mycoprotein"?

"At the moment, we are fully focused on the fish feed industry, where the Norwegian industry naturally has the highest priority, as the world's largest market. We are currently in dialogue with several Norwegian producers", he reveals.

The fish is now sold in selected Hemköp stores (Swedish grocery chain), as well as served at Urban Deli (Swedish restaurant chain) and via Fiskhallen Sorunda (foodservice) to selected restaurants in Stockholm and Gothenburg.

"Have you conducted any parallel studies of the fish and fish health"?

"Yes. Sensory tests conducted by experts at Grythyttan showed that rainbow trout raised on the feed of the future tastes just as good as fish fed with traditional feed."

Öste says that the 'fish of the future' was described as having 'a fresh taste with nutty and mineral tones, as well as a good texture that was soft, slightly juicy and melted in the mouth'.

"The fish maintains the same high quality as fish raised on regular feed - and it grows just as well. For the farmers, this means both new business opportunities and an active contribution to the green shift", he believes.

Scaling up

And with a validated process and a first product on the market, Cirkulär is now moving towards full-scale facilities with a capacity of tens of thousands of tonnes annually.

"In addition to addressing the challenges in the fish feed industry, the goal is to deliver ingredients to a range of different industries - from animal feed and food to skincare and biostimulants", says Öste.

More information about "Fish of the future" can be found here:

https://www.axfoundation.se/nyheter/varldens-forsta-fisk-uppfodd-med-mykoprotein-svensk-satsning-bakom-framtidens-foder

🔗

https://www.axfoundation.se/en/projects/feed-of-the-future

(scroll down to Fish of the future).

SPONSORED ARTICLES

-

Derfor mener vi du skal bruke slike filtre

-

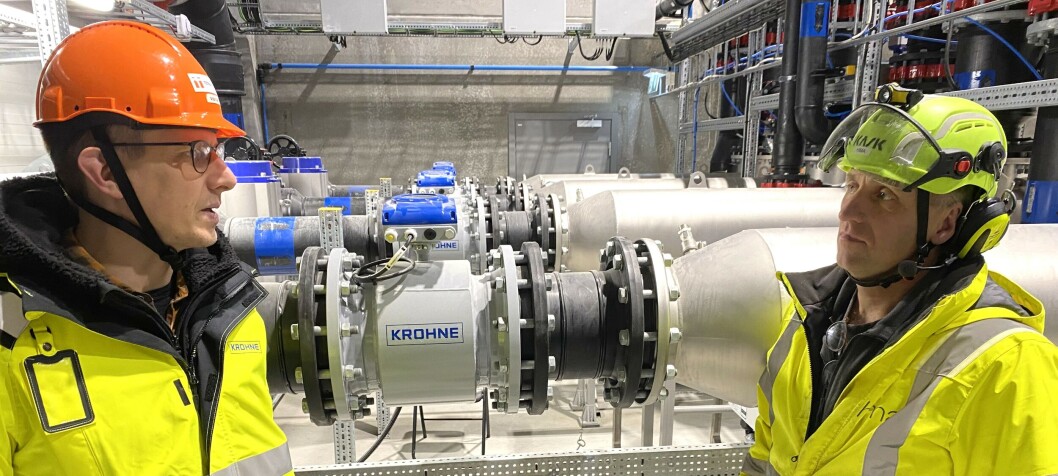

KROHNEs instrumenter er helt sentral i produksjonen

-

Revolusjon i RAS: Skivefiltrenes gjennombrudd

-

Er ditt RAS-anlegg godt rustet mot brann?

-

Høye ambisjoner og en liten dose galskap – Slik ble Havida til!

-

Slik skal Island sikre norsk rognbehov i årene fremover

-

Islandsk Benchmark-rogn ga storfisk produsert på svært kort tid

-

Vikan Settefisk leverer første generasjon fra RAS anlegg

-

Lave omkostninger på oksygen gir merkbart resultat på bunnlinjen

-

Er det behov for genetiske tilpasninger for landbasert oppdrett og RAS-systemer?