Rolling out special paints for land-based aquaculture

The German company Silikal supplies industrial floor coatings to the whole world. Through its European distributor, Norwegian Silikal Nord Vest, it has gained a foothold in land-based aquaculture facilities. Now it is taking the investment a step further.

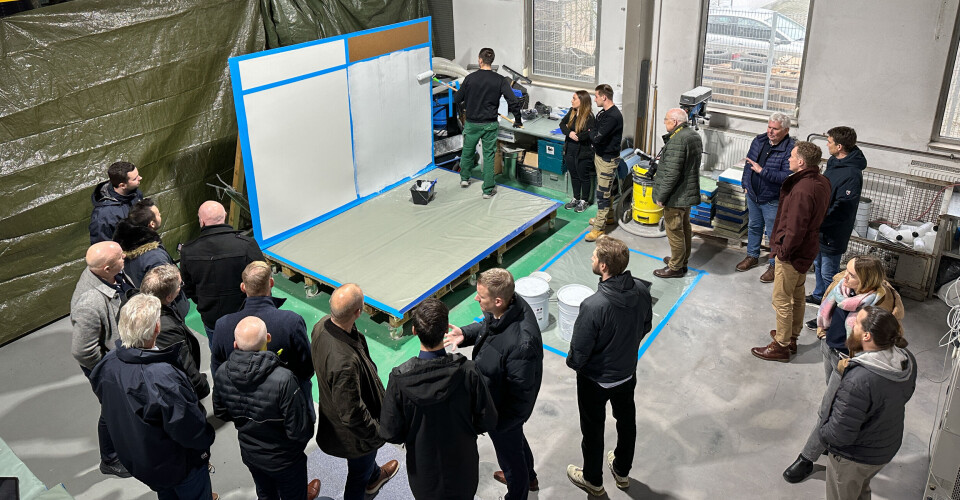

In December, several customers, subcontractors, consulting companies, and national and international press gathered at Silikal's factory in Mainhausen, Germany, to gain insight into how one of the coatings offered to the growing land-based aquaculture industry is developed and produced.

The Norwegian company, Silikal Nordvest, also took the opportunity to pre-launch its new concept for various coatings for land-based aquaculture, which they have called Silikal Aquaculture Solutions.

"We hope that what we are doing now will establish a new form of standard within land-based aquaculture," says the company's managing director, Christian Aas, son of founder Håkon Aas.

The product series that the company has launched consists of various coating systems, where each coating system consists of different layers and membranes assembled into a complete coating with properties specifically developed for land-based aquaculture facilities.

"The coatings are based on industry experience, grounded in real issues, and are specially developed with help from the industry," says Aas.

Research-driven

The producer of the chemistry behind it, Silikal GmbH, provided participants at the factory event with an introduction to the research behind the solutions.

"We have a research department with chemists and technologists who really delve into the various issues. We have to do this if we are to compete in the global market," the head of Silikal GmbH, Henning Simon, told the visitors.

He explained that the basic idea behind the development of the coatings is that they should withstand extreme conditions while ensuring optimal hygiene and long-lasting protection of the facilities.

"Therefore, special requirements for mechanical strength and chemical resistance have also been set."

The story continues below the images.

Different areas

Christian Aas explained that the coatings are specially adapted to the different areas within land-based aquaculture, with their own systems for, for example, recirculating aquaculture systems, fish tanks, and floors.

"By targeting further development towards specific types of tanks and challenges, even more specialisd solutions for the aquaculture industry can be developed," he said.

Methyl methacrylate

The products that Silikal supplies to land-based aquaculture are based on so-called MMA (methyl methacrylate). This is a substance that has a wide range of applications. Products based on this are used both as filling material for cavities at the dentist and as bone replacement in orthopedic surgery. It is also used to make contact lenses. And, of course, to make industrial coatings.

When the coating is to be applied, it is mixed with a hardener/activator (preferably hydrogen peroxide) on site, and then the various layers are applied with a roller.

"In the context of aquaculture, MMA has several good properties. It adheres very well to substrates such as concrete and even polypropylene. It can also be applied in relatively cold environments, it is not very sensitive to humidity during application, and it cures in a short time, often as little as 20 minutes," explained Dr Peter Loh, head of the R&D department.

He said that when a new layer in the coating system is applied, it will activate the surface of the underlying layer, so the layers are almost "welded" together.

"Thus, it becomes both strong and flexible, and can withstand both vibrations and even earthquakes," he said.