Low particle load in RAS is good for both salmon and operation

Recirculating water systems (RAS) rely on water purification to remove waste materials and particles. However, the small particles are difficult to remove, and commercial RAS therefore often have high particle loads. In the recently completed project MicroRAS, researchers in Norway investigated how particle loads affected water quality, microbiota, and salmon health and growth. The results indicate several challenges with elevated particle loads, but also a number of practical advantages with low particle loads.

The article was written by: Ole-Kristian Hess-Erga (NIVA), Sara Calabrese (NIVA), Paulo M. Fernandes (NIVA), Simen Fredriksen (NTNU), Håkon Dahle (UiB), Mark Powell (formerly RASlab), Melanie Andrews (RASlab) and Ingrid Bakke (NTNU).

RAS are complex systems and a number of interdependent processes take place that affect both water quality and fish growth. The understanding of this complex system is increasing, and improved procedures and guidelines for the best possible operation and fish production are being established. Nevertheless, there is great variation in how RAS are operated and how successful fish production is.

Most salmon farming companies in RAS experience challenges with elevated particle levels in the water despite continuous drum filtration of the operating water. Such particles largely consist of organic material that is added to the water via the feed and the fish's faeces.

From previous studies and experience, it is known that such organic material provides a breeding ground for increased growth of bacteria and other microorganisms in the biofilters and in the water. This can lead to reduced biofilter capacity and increased growth of fast-growing bacteria in the water that can have negative effects on the health of the fish.

Furthermore, it can lead to the production of adverse metabolites such as geosmin and toxic H2S (hydrogen sulphide). In addition, reduced visibility in the water can affect the salmon's feed intake and the farmer's ability to observe the fish. However, the exact direct and indirect effects of particles and organic material on the fish are uncertain and are being discussed in the industry. Increased knowledge in this area will make us better able to assess which measures are good for the salmon and the operation of the RAS.

Long-term experiments in RAS and simulated exposure to marine facilities

To study the effects of particle loading on salmon in RAS, a long-term experiment was conducted in 6 RAS units and then a simulated transport and simulated release to sea facilities. In the RAS phase, a particle loading was chosen that corresponds to conditions commonly found in commercial RAS (approximately 7 mg total suspended solids (TSS) per litre, called high TSS/HTSS) and conditions that many may wish to achieve (1-2 mg TSS/l, called low TSS/LTSS). We increased the particle loading in the HTSS group by returning particles from the swirl and drum filters, and each RAS had the same biomass and feeding intensity.

Main findings

Particle levels commonly found in commercial RAS can have negative effects on salmon performance, such as increased feed factor, reduced condition factor and growth, and can delay smoltification. Compensatory growth in the sea phase indicates that the particle levels/conditions tested are within the fish's range of adaptation and compensation, but that this is energy-demanding for the fish.

Histological examinations showed no signs of negative effects on gill and skin health. However, gene expression of inflammatory markers increased in fish exposed to high particle loads in both gills and skin, particularly towards the end of the RAS phase. This may be an early sign that more profound adverse health effects are developing.

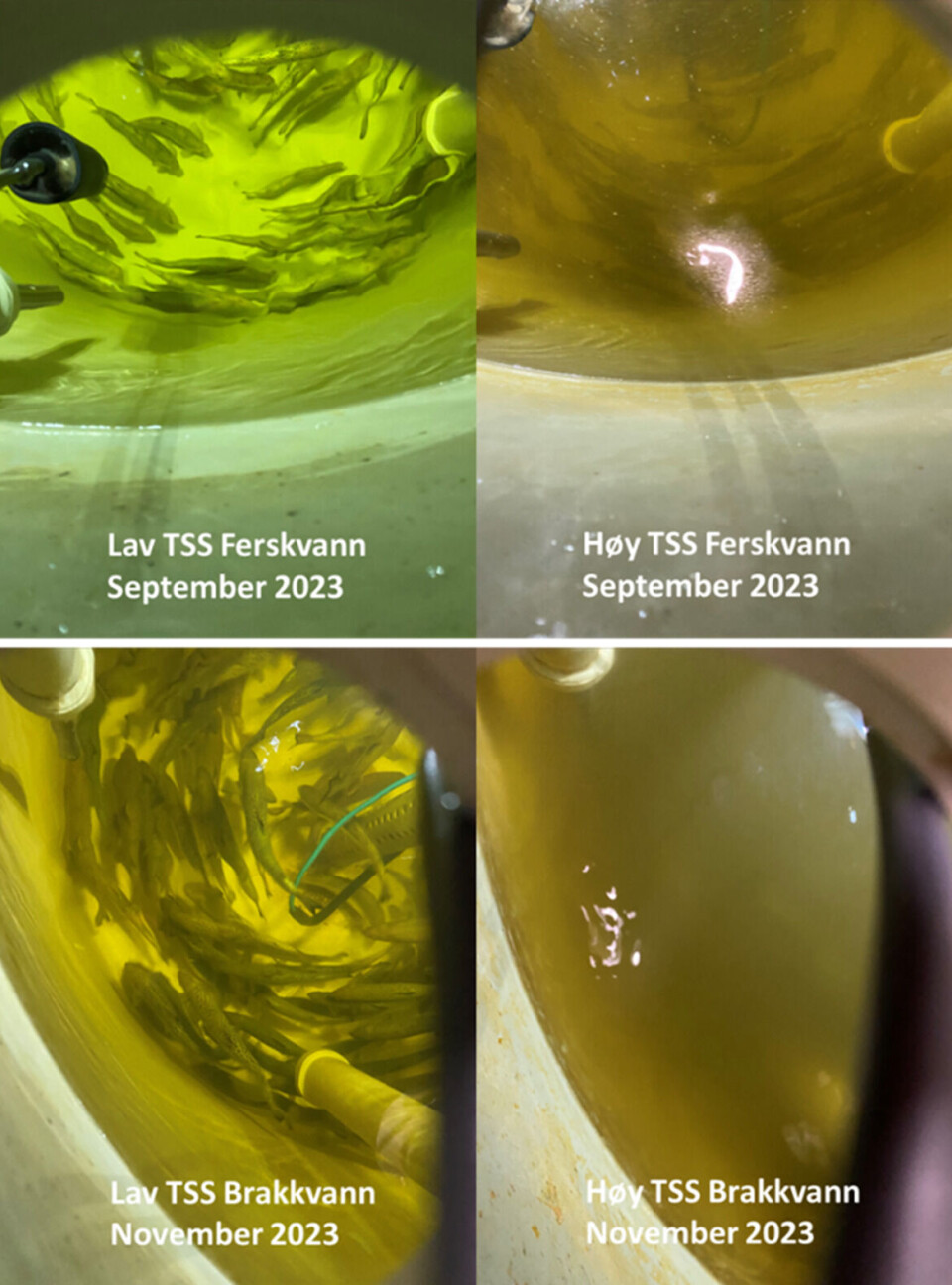

Levels of suspended solids (TSS) around 7 mg/l in the RAS led to significantly reduced water clarity ( Figure 1 ) and reduced nitrification rates. There was an increased abundance of heterotrophic bacteria in the water and biofilter during the transition to brackish water, and we observed higher concentrations of ammonium and nitrite in the RAS with higher particle loading. This suggests reduced biofilter capacity, probably due to out-competing nitrifying bacteria in the biofilter.

Low particle loading can also lead to a number of practical advantages, such as easier cleaning and easier observation of the fish, as well as better effect of water treatment (aeration of CO₂, disinfection, nitrification, etc.) and probably reduced risk of bacterial production of unwanted metabolites (e.g. H₂S and geosmin).

There may be several reasons for reduced fish growth under elevated particle loading. Under suboptimal water quality, fish use more energy for compensatory physiological adaptations to maintain a stable internal environment (homeostasis). How much energy is used to find and possibly compete for food, in an environment with limited visibility, is unclear. It is conceivable that the delayed smoltification is due to uneven and reduced light and/or that particles had direct disruptive effects on the function of the gill chloride cells. In addition, production intensity, temperature and elevated levels of other waste products and metabolites could negatively affect fish production.

Since there is great variation in how RAS is operated and how successful fish production is, it will be important to ensure a common understanding of several such key factors and identify premises for operation through exchange of experience and further research. These are all important pieces for the best possible fish production.

Importance for the industry

The findings from MicroRAS indicate that particle levels commonly found in commercial RAS negatively affect fish performance in RAS and may delay the timeline for smoltification. Therefore, it may be worthwhile to introduce measures to reduce the input of organic matter to the water and improve particle removal. Relevant measures may include optimisation of a farmer's own operations and contributions to methodological innovations, as well as development of equipment that ensures better particle removal.