Launching an entirely new tank system for hatcheries

AmfiTop Aqua Farming Ltd. aims to challenge plastic and concrete with modular aluminium tanks coated with Solid Surface.

The company, originating from Bergen, is focusing on modular aluminium fish tanks, coated with a "Solid Surface material" – also based on aluminium – which they claim offers better fish health, easier logistics, and a more sustainable alternative to plastic and concrete.

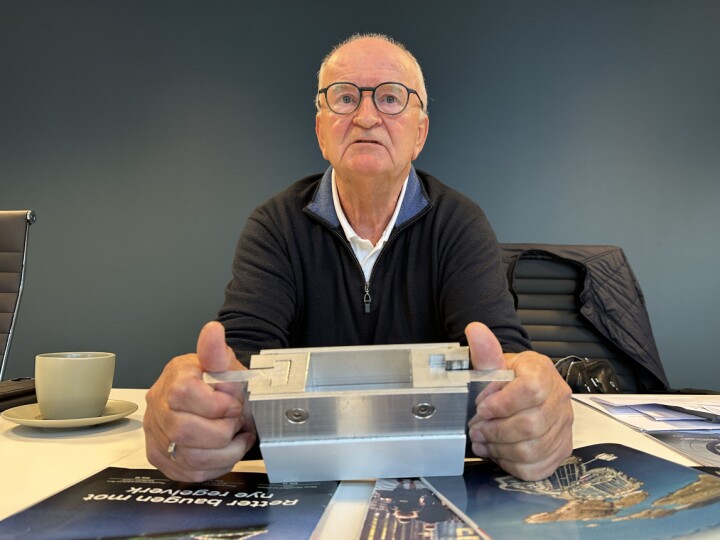

The idea was developed by Svein Fürstenberg from Søreide in Ytrebygda. When LandbasedAQ meets him in Bergen, he lays drawings and sketches on the table and speaks enthusiastically about the tanks the company has developed.

Fürstenberg is CEO of AmfiTop Solid Surface.

“I have more than 25 years of experience with Solid Surface material in the production and development of specialised products for hotels and ships.

The company delivers, for example, bathroom furnishings and sinks for hotel chains such as Scandic, Radisson, and Citybox. In addition, bathroom interiors for luxury yachts built at yards in Romania.

I believe I can safely say I was the first in Europe to use solid-surface under the curing principle. Today there are 6–8 producers of this.”

Norwegian-owned company

AmfiTop is a Norwegian-owned company, but production takes place under license in Latvia.

“Today we are a small but specialised organisation with eight committed partners,” says Fürstenberg.

The company that will produce aquaculture tanks has been named AmfiTop Aqua Farming Ltd.

An idea takes shape

The move into aquaculture started back in 2021.

“I was contacted by an acquaintance working with the Viking Aqua project. He told me how challenging traditional tank solutions in plastic and concrete were in terms of durability, maintenance, and construction.

He asked if it would be possible to produce tanks in environmentally friendly aluminium lined with Solid Surface material on the fish side, tanks that were easy to transport and assemble.

That experience I have now brought into aquaculture, where I see great potential.

I quickly realised this could be an opportunity. All my production experience told me that Solid Surface material was very well suited for fish farming tanks when it comes to fish health, hygiene, durability, and cleaning.

In Latvia, I had production expertise and capacity, and I quickly understood this could be a product the aquaculture industry would definitely need.”

Therefore, Fürstenberg set out to develop a product that has only recently been certified.

Built like a “pizza”

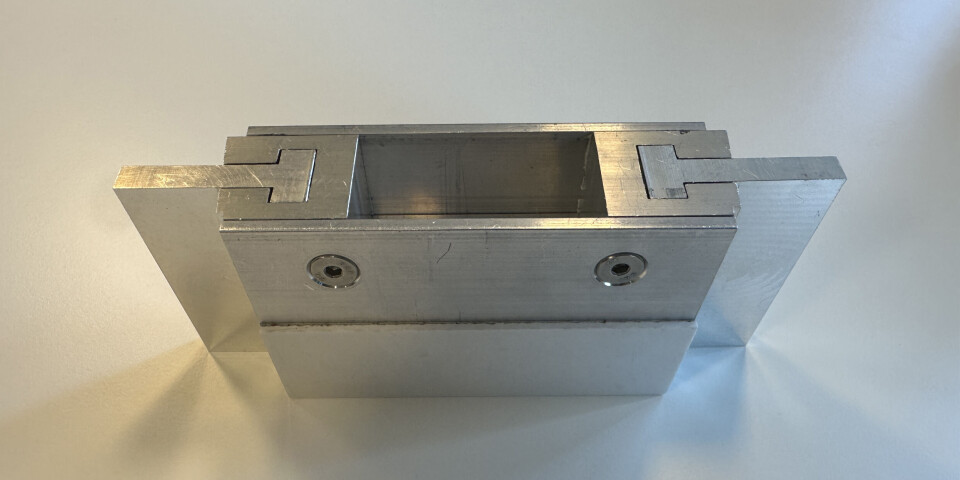

The tanks being developed in Latvia are modular.

“Our tanks are built up from aluminium module elements, with floors assembled like a giant ‘pizza’. The wall elements are also modular, with a patented locking mechanism between each module. Everything is glued together on site with ordinary Tec7, and bolted to the floor with brackets on the outside of the tank wall.

Because it is modular, it offers practical advantages during both transport and assembly.

Our tanks are pallet-packed and easy to transport by truck. They are quick to assemble and come in various sizes.

A test tank was assembled in 2.5 hours.”

On the inside, the surface is carefully chosen.

“Solid Surface inside the aluminium modules provides an antiseptic, smooth, and durable surface. It is easy to clean, and it promotes good fish health,” he explains.

Fürstenberg highlights several reasons why aluminium was chosen for the modules.

“Aluminium provides strength and low weight. That means simpler logistics and very fast assembly. Aluminium is also 100% recyclable. Our authorities have decided to actively reduce the use of plastic and cement, and this is the way forward.

For example, if a new smolt facility needs 40 large plastic tanks, 50 tonnes of plastic will be required just for that one site. And there are 50 to 100 facilities to be built,” he says.

Certification

To deliver this type of component into the Norwegian aquaculture industry, they must be certified by one of the approved certification bodies in Norway.

AmfiTop chose Aquastructures for this.

“They have been working on our certification for two years, resulting in more than 100 densely written A4 pages. The process has been incredibly demanding,” he admits.

A pilot tank was built in Latvia, which has now been dismantled.

And halfway through the process, it turned out they would also need earthquake approval for the product.

“We had Riga Technical University carry out tests. They also do such work for Airbus, among others, so they know what they are doing.

For four months they performed calculations, which resulted in a report that was forwarded to the earthquake research foundation NORSAR in May. They then passed on their conclusion to Aquastructures, which finally approved the product this summer.

So only now can we actively start marketing and sales,” says Fürstenberg.

Smolt and post-smolt

The company intends to produce tanks in different sizes and volumes for various purposes.

“We offer tanks with diameters from 6 to 19 meters, heights from 1.25 to 4.0 meters, and volumes from 28 to 1000 m³.

The tanks are primarily designed for smolt and post-smolt and can only be used for indoor production. Fürstenberg also emphasises durability and economics.

The service life of our tanks is significantly higher than plastic solutions, while maintenance needs are low. The overall cost picture is highly favourable, as one of our tanks can easily be assembled in a day.

It has also passed saltwater, acid, and fire tests with flying colours,” he adds.

They are now looking for a site to set up tanks for a demonstration project, so they can start production.

“We can build the production line in 30 days. We will do that as soon as we have the first order,” he concludes.

Watch video of the assembly of the first pilot tank. Video: AmfiTop Aqua Farming Ltd.