Aquafarm strengthens its professional team

Norway: With two new hires, the specialist company in closed containment salmon farming centers projects sustained growth, awaiting government incentives for these types of structures.

The former production manager of Mowi Ireland, Roar Paulsen, has joined the Norwegian specialist in closed floating containments Aquafarm Equipment as senior vice president.

"Roar knows the industry and the industry knows Roar, both abroad and in Norway. We believe it is a perfect match," said Aquafarm CEO Jarle Lønning in a press release.

Paulsen was the operations director in Ireland for 18 months, from January 2023 until June of this year. Before that, he was the production director of Mowi Scotland from May 2021. He also spent nine years as the production director of the central Norway division of the salmon farmer Lerøy.

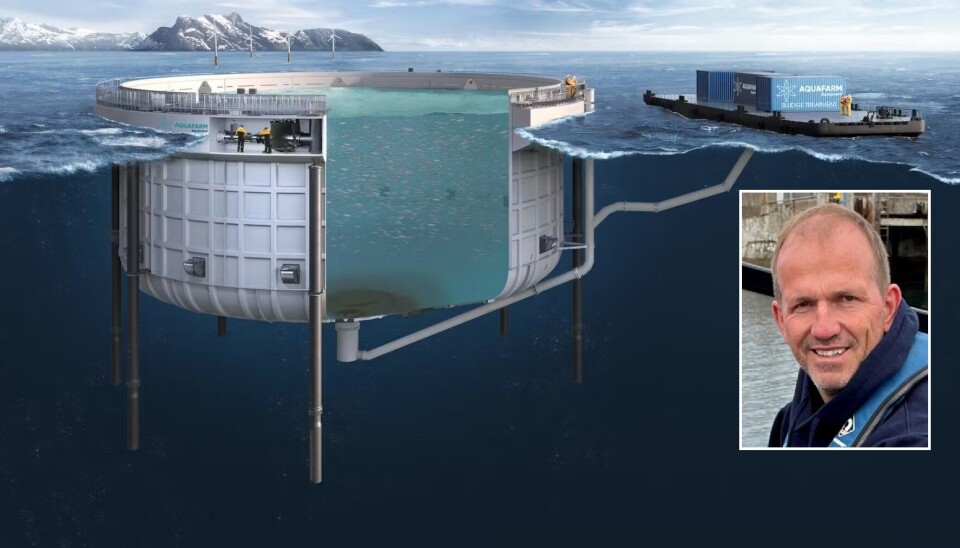

The closed floating Aquafarm system is built with several GRP (glass-reinforced plastic) panels. It has a circumference of 126 meters, a depth of 22 meters, and a gross volume of 21 thousand m3.

Mowi Norway has carried out large-scale tests of the system for the production of post-smolt, but it is also designed for the growth of fish up to harvest size and for broodstock. Mowi Scotland also considered the use of Aquafarm's Neptune cages for the production of post-smolt, but for now it relies on open cage farming in Loch Etive, which has low salinity and fewer sea lice than other marine lakes.

Better control

"I have dedicated much of my career to improving framework conditions, securing operations, and accelerating the pace of innovation in the aquaculture industry. If we want to continue developing this industry, I am convinced that we must acquire better control over the fish environment and water quality," stated Paulsen.

"Aquafarm has impressively developed a sustainable and profitable way to improve the aquaculture industry, and I am very eager to be part of this future work," the professional emphasized.

Lønning said that Paulsen's appointment would help strengthen the company's commitment to sustainable production in Norway and abroad.

"Our industry must think in a completely new way. About fish welfare. About lice. About escapes. As we eagerly await the new environmental technology plan from the government in Norway, rapid and far-reaching changes are occurring beyond the country's borders. The demand for sustainable aquaculture is increasing, as is the need for fish. We want to be part of the solution for sustainable food production in the future and, therefore, we must be present where the changes are taking place," he stated.

New Chief Financial Officer

Aquafarm Equipment also hired Benedikte Tveit from Alde Akva, an independent consultant offering advisory services on land-based aquaculture facilities and closed marine cages. Tveit will be the new Chief Financial Officer of the company.

"Our industry requires a lot of capital and with Benedikte Tveit we have a person with solid project management experience. She is also a smart person in business development," said Lønning.

The company expects the Norwegian government to finally offer good incentives for sustainable and closed production and to position itself for major market changes.

"Many markets and countries are stepping on the accelerator, and if incentives for closed systems are not applied soon, Norway will lose competitiveness. With Benedikte and Roar on board, we lead the team and are prepared both inside and outside of Norway," said Lønning.

Technology

The closed floating Aquafarm system has been developed in collaboration with Marintek, DNV GL, Norconsult, Multiconsult, and SINTEF, and has been thoroughly tested and certified.

To withstand environmental forces and ensure stability, a large floating collar has been mounted on the cage. The floating collar facilitates water treatment systems, which consist of filters, ultraviolet light, and oxygenation equipment. This system treats and disinfects the incoming water according to regulatory requirements.

The incoming water is drawn from a depth of 25 meters and is pumped through separate treatment systems before being released into the tank. It is said that a patented hatch system ensures a double escape barrier configuration for fish and an exceptional hydraulic flow within the enclosure. "This method allows us to completely avoid the problem of fish lice," said Aquafarm.